Fresh Cut Flower Cultivation Trough Planting System

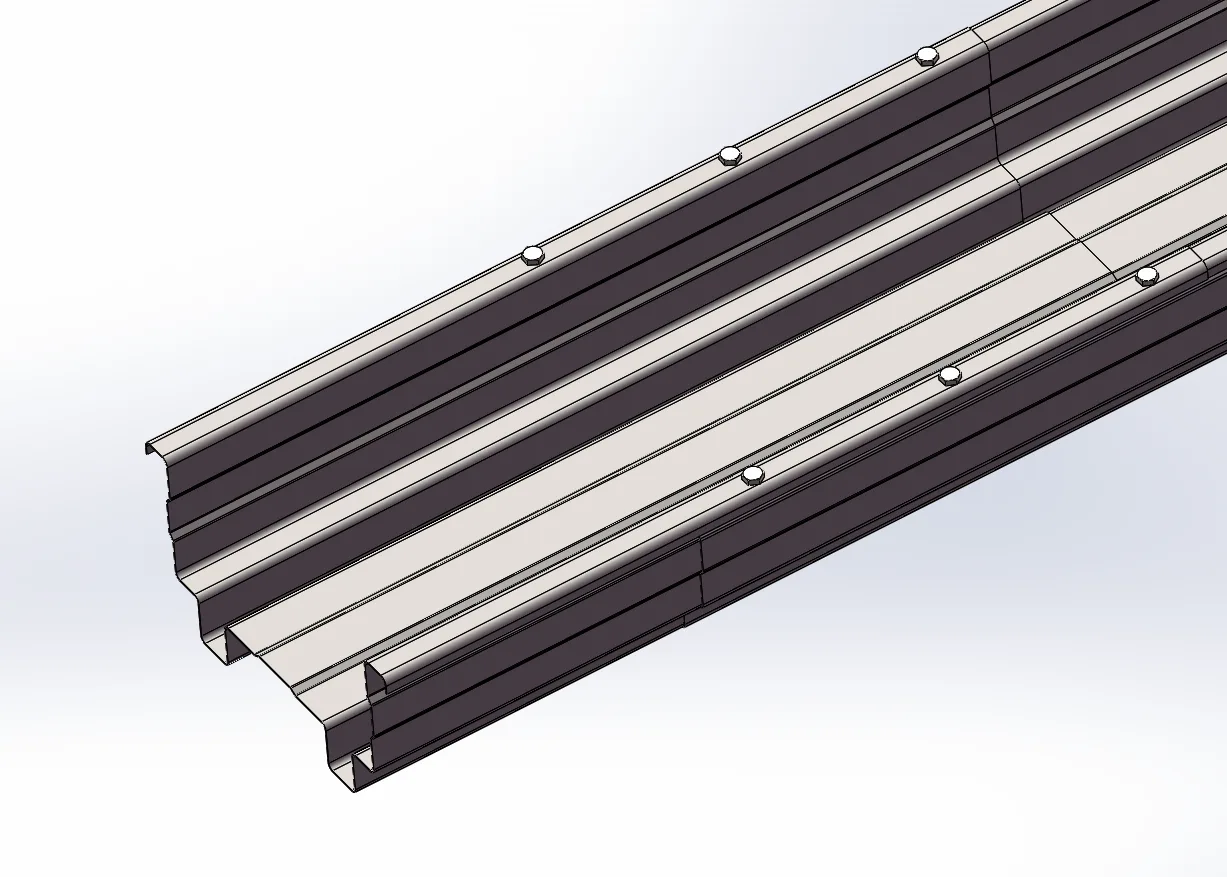

- The system includes support troughs, drainage troughs, and continuous base plate supports. The support troughs are made of 150g fingerprint-resistant aluminum-zinc coated plates, 0.8mm thick, with five 176mm-diameter holes per meter.

- The drainage troughs are made from high-durability polyester-coated plates, with a thickness of 0.7mm and can be produced continuously on-site.

- The continuous base plate structure ensures the overall stability of the system.

Cut-Flower Cultivation Techniques’ Characteristics

- High yield and profit per unit area. For example, roses yield 100-150 stems/m² annually, and chrysanthemums yield 60-80stems/m².

- Cultivation is scaled and standardized, with controlled facilities for intensive harvesting and year-round supply.

- High consumer demand and broad market for cut flowers.

- High cultivation costs and risks, but significant economic benefits.

Application and Summary

- The substrate cultivation technology for fresh cut flowers has been integrated, and the system for automatic sorting and intelligent packaging has been developed.

- An efficient green production system for cut roses has been established, reducing labor and post-harvest losses, and extending vase life by 5-10 days.

- The planting trough system enhances production efficiency and quality, aiding in the automation and scaling of cut flower cultivation, which is crucial for the flower industry’s development.